Blog

High End Cutting and Engraving Machines Precision Meets Innovation

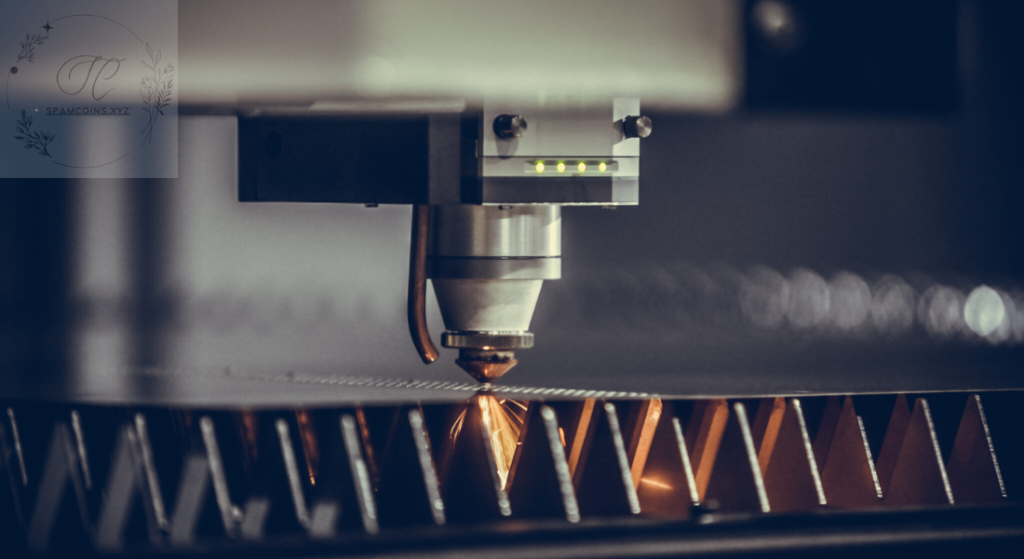

High end cutting and engraving machines are revolutionizing industries with their unmatched precision and versatility. Whether you’re in manufacturing, design, or crafting, these machines ensure your projects are executed with perfection.

Their advanced capabilities offer solutions for various industries, combining speed, accuracy, and reliability into one powerful tool.

Precision Redefined with High End Cutting and Engraving Machines

One of the standout features of high end cutting and engraving machines is their exceptional accuracy. These machines are designed to handle intricate cuts and detailed engravings, ensuring flawless results every time.

For industries like aerospace, jewelry, and custom fabrication, precision is non-negotiable, and these machines deliver unmatched results that meet even the most demanding standards.

The Speed Advantage of High End Cutting and Engraving Machines

Efficiency is a critical factor in production, and high end cutting and engraving machines excel in this area. By combining cutting-edge technology with fast processing speeds, they complete projects quickly without compromising quality.

This speed not only increases productivity but also allows businesses to take on more projects, maximizing profitability.

Advanced Technology in High End Cutting and Engraving Machines

Modern high end cutting and engraving machines utilize state-of-the-art technology, such as laser systems, CNC programming, and AI integration. These features simplify complex tasks, making them accessible for users of all skill levels.

Automation ensures consistent results, while smart interfaces provide an intuitive experience, allowing operators to focus on creativity and innovation.

Applications of High End Cutting and Engraving Machines

High End Cutting and Engraving Machines in Manufacturing

Manufacturing relies heavily on precision and efficiency, and these machines excel in producing high-quality components. From automotive parts to aerospace materials, they handle a wide range of applications with ease.

Their ability to cut and engrave various materials, including metals, plastics, and composites, makes them indispensable for modern manufacturing processes.

High End Cutting and Engraving Machines for Jewelry Design

Jewelry designers benefit from the intricate detailing capabilities of these machines. High end cutting and engraving machines allow for the creation of intricate patterns, fine text, and custom designs, transforming raw materials into stunning pieces of art.

This precision ensures every piece meets the high standards of the jewelry industry, enhancing customer satisfaction and brand reputation.

High End Cutting and Engraving Machines in Art and Design

Artists and designers use high end cutting and engraving machines to bring their visions to life. These machines handle complex patterns and unique designs, enabling the creation of personalized products, sculptures, and installations.

Their versatility empowers creatives to experiment with different materials and push the boundaries of their work.

High End Cutting and Engraving Machines for Signage and Branding

For businesses, signage is a critical component of branding, and these machines deliver high-quality results that stand out. Whether engraving logos or cutting detailed letters, high end cutting and engraving machines ensure professional-grade finishes that leave a lasting impression.

Advantages of Premium Cutting and Engraving Technology

Durability Built for the Long Haul

Advanced cutting and engraving tools are designed for resilience. Their sturdy construction ensures reliable performance for years, even in challenging work environments.

This robustness makes them an economical choice for professionals and businesses seeking dependable equipment that stands the test of time.

Versatile Across Multiple Materials

These machines excel in versatility, handling a wide range of materials effortlessly. From metals and wood to textiles and acrylics, their adaptability opens doors to unlimited creative and functional applications.

Energy-Conscious Performance

Sustainability is a key focus for modern industries, and these tools meet the mark with energy-efficient designs. By optimizing power consumption, they reduce operational costs and environmental impact.

This balance between exceptional performance and eco-consciousness helps businesses maintain high standards while supporting green initiatives.

Safety Features That Inspire Confidence

Safety-enhancing elements like enclosed structures, auto shut-off systems, and protective shields ensure operators can focus on their work without unnecessary risks.

These thoughtful additions provide a secure and stress-free environment for operators, prioritizing both productivity and peace of mind.

Customization and Expansion Opportunities

Tailored Features for Specific Needs

Modern machines offer personalized settings and configurations, catering to unique project requirements. Software customization and physical modifications allow users to fine-tune tools to their exact specifications.

Supporting Growth and Scale

For expanding businesses, these tools provide scalability. Their efficiency and adaptability enable companies to manage increased workloads, cater to higher demands, and explore new markets seamlessly.

Insights from Industry Experts

Transformational Impact Across Industries

Professionals across diverse sectors commend these machines for their ability to enhance efficiency and deliver superior quality. From artisans to industrial manufacturers, users emphasize the role these tools play in boosting workflow and maintaining competitive advantage.

Forward-Thinking Features

Intelligent Technology for Smarter Operations

Cutting-edge advancements like AI integration simplify tasks and optimize performance. These systems adapt to user needs, ensuring consistent precision with minimal intervention.

Remote Capabilities for Seamless Management

Cloud-connected solutions enable remote project handling, real-time collaboration, and smooth design sharing. These features enhance productivity and ensure seamless integration into modern workflows.

Why Investing in Cutting and Engraving Tools Makes Sense

Long-Term Reliability and Value

Although these tools may require an upfront investment, their reliability and efficiency offer lasting value. Professionals benefit from reduced operational costs and enhanced project outcomes over time.

Gaining an Industry Advantage

In competitive industries, precision and speed are essential. These tools equip businesses to meet demanding standards, exceed customer expectations, and maintain a leading position in their market.

Empower Your Craft with Cutting and Engraving Technology

Advanced cutting and engraving tools elevate creativity, precision, and efficiency. Whether in manufacturing, design, or artistry, these machines empower professionals to achieve remarkable results with ease.

Take your projects to the next level with these high-performance tools. Experience unmatched craftsmanship, reliability, and innovation by upgrading today.