Blog

CNC Lathe Machines for Cutting The Future of Precision Manufacturing

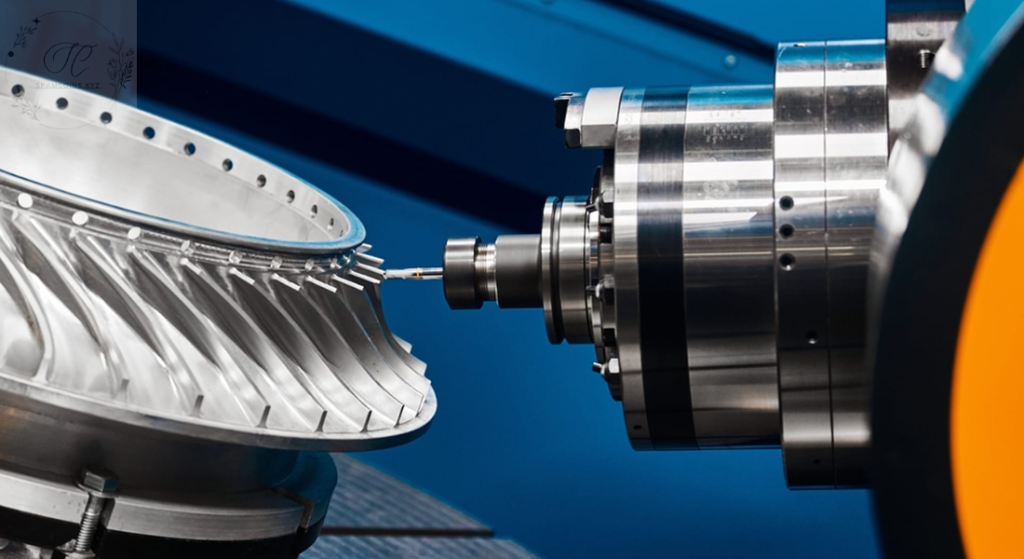

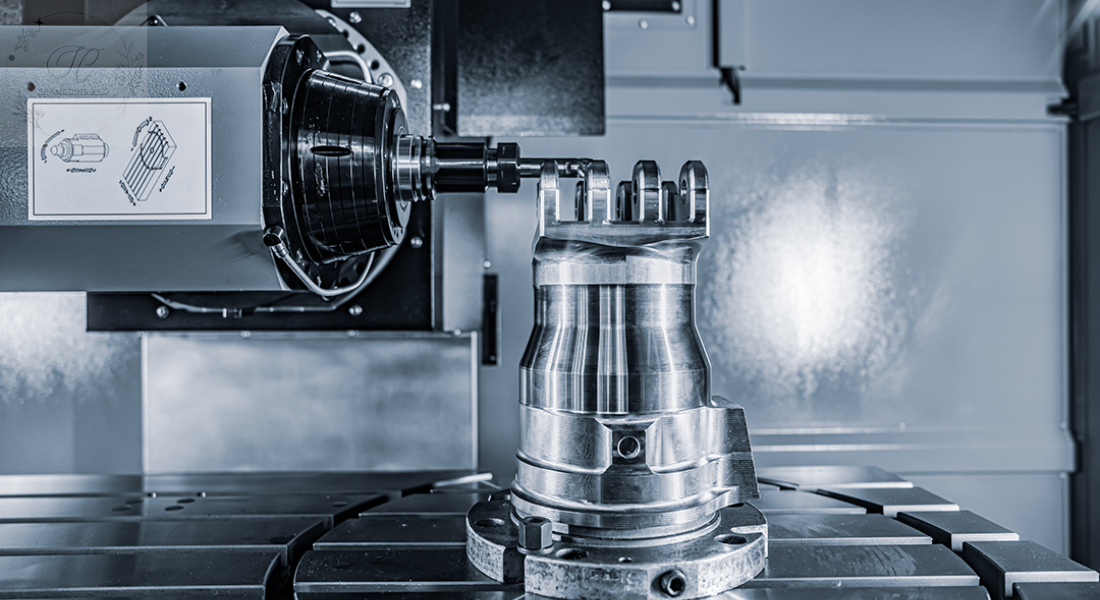

CNC lathe machines for cutting have revolutionized manufacturing by delivering unparalleled precision, efficiency, and versatility. These state-of-the-art tools are essential for industries requiring high-quality results and faster production cycles. Whether shaping metals, plastics, or composite materials, CNC lathe machines are the backbone of modern fabrication.

Mastering Precision with CNC Lathe Machines

CNC lathe machines for cutting excel in producing intricate designs and flawless finishes.

- Advanced Programming

Their computer-controlled systems enable highly accurate cuts, even on complex geometries, ensuring every piece meets exact specifications. - Repeatability

Once programmed, these machines replicate the same design flawlessly, eliminating errors and reducing material waste. - Micro-Level Accuracy

Capable of operating at tolerances as tight as a few microns, CNC lathe machines for cutting set the standard for precision.

Unlocking Speed and Efficiency

CNC lathe machines for cutting transform production lines by streamlining workflows and reducing manual intervention.

- Fast Setup

Pre-programmed instructions eliminate the need for lengthy setup times, allowing operations to begin quickly. - Continuous Operation

These machines run for extended hours without breaks, meeting high-volume demands with ease. - Optimized Tool Paths

Software-driven paths ensure minimal tool wear and faster cutting cycles, boosting productivity.

Versatility Across Materials

CNC lathe machines for cutting adapt seamlessly to different materials, making them ideal for various industries.

- Metal Fabrication

From steel and aluminum to titanium, these machines shape metals with unmatched precision. - Plastic Components

Cutting softer materials like plastics requires finesse, which CNC systems handle effortlessly. - Composites and Alloys

Industries like aerospace and automotive rely on CNC lathe machines for cutting complex composite materials.

Enhancing Operator Control

Modern CNC lathe machines for cutting offer user-friendly interfaces, putting advanced capabilities at operators’ fingertips.

- Intuitive Software

Advanced CAD/CAM software simplifies the creation of detailed designs, reducing the learning curve for operators. - Real-Time Monitoring

Operators can track cutting progress and make adjustments mid-process, ensuring optimal results. - Customizable Settings

Tailor settings like speed, feed rate, and tool angles to suit specific material properties or project requirements.

Perfect for Complex Designs

CNC lathe machines for cutting are engineered to tackle even the most intricate designs with ease.

- 3D Contours

Achieve smooth, complex shapes ideal for medical devices, jewelry, and automotive parts. - Thread Cutting

Precision threading capabilities make these machines indispensable for fastener production. - Multi-Axis Operations

Advanced models handle multi-axis cutting, enabling the creation of detailed and multi-faceted components.

Ideal for Small Businesses and Large Enterprises

Whether you’re running a small workshop or a global manufacturing hub, CNC lathe machines for cutting adapt to your needs.

- Small Workshops

Compact models offer affordability and flexibility, allowing small businesses to expand their capabilities. - High-Volume Production

For large-scale manufacturers, automated systems deliver consistent results at high speeds. - Prototyping and Customization

Quickly produce prototypes or bespoke designs without expensive molds or tooling.

Driving Cost Efficiency

CNC lathe machines for cutting offer cost-saving advantages that benefit both businesses and end-users.

- Material Savings

Precision cutting minimizes waste, making the most out of expensive materials. - Reduced Labor Costs

Automation reduces the need for manual intervention, cutting down on labor expenses. - Long Tool Life

Optimized tool paths and advanced cooling systems prolong the lifespan of cutting tools.

Essential for Critical Industries

CNC lathe machines for cutting play a pivotal role in industries demanding high standards of quality and precision.

- Aerospace

These machines craft turbine blades, engine parts, and other critical components to exacting specifications. - Medical Devices

Precision is vital in creating surgical instruments, implants, and diagnostic equipment. - Automotive

From gears to engine parts, CNC lathe machines are essential for crafting durable and reliable components.

Staying Ahead with Technology

CNC lathe machines for cutting continually evolve, incorporating new technologies to improve performance and usability.

- AI Integration

Artificial intelligence enhances programming efficiency, predictive maintenance, and tool optimization. - Smart Sensors

Integrated sensors monitor tool wear and machine performance, ensuring consistent results. - Remote Operation

Cloud-based systems allow operators to monitor and control machines from anywhere, boosting flexibility.

Investing in Quality Equipment

Selecting the right CNC lathe machines for cutting is crucial for maximizing productivity and profitability.

- Trusted Brands

Choose manufacturers known for reliability, innovation, and robust after-sales support. - Machine Specifications

Match machine capabilities with your production needs, considering factors like speed, precision, and size. - Training and Support

Invest in comprehensive training for operators to ensure efficient and safe machine use.

Innovations Driving the Future

The future of CNC lathe machines for cutting promises even greater capabilities, opening new possibilities for manufacturers.

- Hybrid Machines

Combining cutting, milling, and additive manufacturing, hybrid machines offer all-in-one solutions. - Eco-Friendly Operations

Advances in energy efficiency and material recycling make CNC processes more sustainable. - Enhanced Automation

Robots and automated loaders further reduce downtime and increase production speeds.

Real-Life Success Stories

Businesses worldwide are thriving with CNC lathe machines for cutting at the heart of their operations.

“Our production line became faster and more efficient, doubling our output within months.”

“The precision we achieved allowed us to enter new markets with demanding quality standards.”

“Switching to CNC lathe machines transformed our small workshop into a competitive manufacturing business.”

Maintenance for Long-Term Performance

Proper care ensures CNC lathe machines for cutting remain in peak condition, delivering consistent results.

- Regular Inspections

Check for alignment, lubrication, and tool wear to prevent costly downtime. - Software Updates

Keep software current to access the latest features and compatibility improvements. - Scheduled Servicing

Partner with professionals for routine maintenance, ensuring your machine operates efficiently.

Competitive Edge in Manufacturing

CNC lathe machines for cutting provide businesses with the tools to stay ahead in competitive industries.

- Faster Turnaround

Shorten lead times and deliver projects on schedule without compromising quality. - Custom Capabilities

Offer clients bespoke solutions, setting your services apart from competitors. - Improved Reputation

Consistent high-quality results enhance your brand’s credibility and attract new customers.

Start Your CNC Journey Today

Investing in CNC lathe machines for cutting is more than a business decision—it’s a step toward modern manufacturing excellence. These machines empower businesses to produce with precision, efficiency, and innovation, ensuring long-term success in a rapidly evolving market. Upgrade your operations with CNC technology and unlock the full potential of your production capabilities.