Blog

High Tech Milling Machines for Tool Making Precision and Innovation Redefined

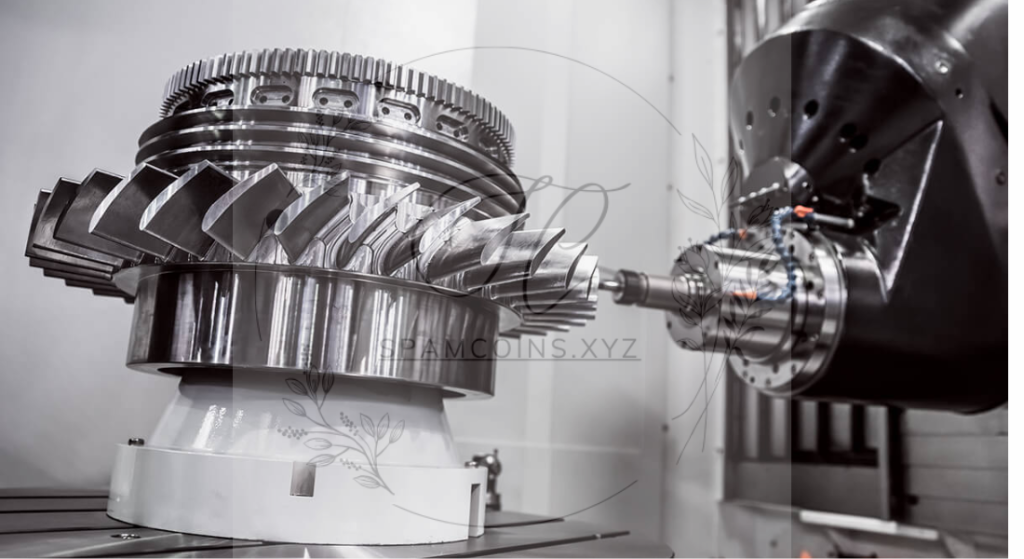

In the world of manufacturing, precision and efficiency are key to producing high-quality tools. High tech milling machines for tool making are revolutionizing industries with cutting-edge technology, unparalleled accuracy, and versatile capabilities. These machines are essential for modern toolmakers looking to create intricate designs and maintain competitive edges.

The Role of High Tech Milling Machines in Tool Making

Precision That Defines Excellence

Tool making demands extreme precision. High tech milling machines deliver the accuracy required for intricate designs and tight tolerances. From molds to dies, these machines produce components that meet the most stringent specifications.

Streamlining Complex Processes

Advanced milling machines simplify complex manufacturing tasks. With features like multi-axis movement and automated programming, they handle detailed operations with ease, reducing manual effort and production times.

Adaptability Across Industries

High tech milling machines for tool making serve a wide range of industries, including automotive, aerospace, medical, and electronics. Their ability to work with various materials, from metals to composites, makes them indispensable in diverse applications.

Features That Set High Tech Milling Machines Apart

Multi-Axis Capabilities for Intricate Designs

Modern milling machines feature 3-axis, 4-axis, and even 5-axis configurations, enabling the creation of complex geometries. These additional axes allow for advanced contouring, undercuts, and seamless transitions in intricate tool designs.

CNC Integration for Unmatched Efficiency

Computer Numerical Control (CNC) integration enhances precision and repeatability. Programmable controls enable operators to execute complex tasks with minimal errors, ensuring consistency in large-scale production.

High-Speed Machining for Faster Output

High tech milling machines operate at remarkable speeds, enabling faster production without compromising quality. This efficiency is especially beneficial for tool making, where tight deadlines are common.

Automated Tool Changers for Continuous Operation

Automated tool changers streamline the manufacturing process by switching tools without manual intervention. This feature enhances productivity and reduces downtime, allowing for uninterrupted machining.

Benefits of Using High Tech Milling Machines for Tool Making

Reduced Production Time

High-speed operations and automation significantly cut down production times. By minimizing manual tasks, these machines optimize workflows and increase overall efficiency.

Enhanced Quality and Consistency

With precise control and repeatable accuracy, high tech milling machines ensure every tool meets exact specifications. This consistency improves product quality and reduces waste.

Cost Savings Through Efficiency

While the initial investment in high tech milling machines may be significant, their efficiency and reduced labor requirements lead to long-term cost savings. Faster production and fewer errors contribute to a more profitable operation.

Versatility in Material Handling

From aluminum and steel to titanium and composites, these machines handle a variety of materials with ease. Their adaptability allows manufacturers to take on diverse projects without the need for multiple machines.

Top Applications of High Tech Milling Machines

Mold and Die Making

Molds and dies are fundamental in manufacturing. High tech milling machines create these components with exceptional detail and accuracy, ensuring they meet the demands of mass production.

Custom Tool Fabrication

For specialized industries, custom tools are often required. Milling machines enable the production of bespoke components tailored to specific applications, from medical instruments to aerospace parts.

Prototyping and R&D

In research and development, milling machines are invaluable for prototyping. They allow designers to test and refine their ideas quickly, accelerating innovation cycles.

Small Batch Production

For manufacturers requiring small production runs, high tech milling machines provide cost-effective solutions. Their flexibility and precision ensure each piece meets exact requirements.

Choosing the Right Milling Machine for Tool Making

Assess Your Production Needs

Evaluate the complexity of your projects, material types, and production volumes. Choose a machine that aligns with your specific requirements to maximize efficiency.

Consider Machine Size and Capacity

Ensure the machine you select fits your workspace and handles the sizes of tools you intend to produce. Larger machines accommodate bigger projects, while compact models are ideal for limited spaces.

Focus on Technology and Features

Look for machines with advanced features like CNC controls, multi-axis capabilities, and high-speed operation. These technologies enhance performance and future-proof your investment.

Prioritize Durability and Reliability

Invest in a milling machine from a reputable manufacturer known for quality and support. Durable machines reduce maintenance costs and ensure consistent operation over time.

Leading Brands in High Tech Milling Machines

DMG MORI

DMG MORI offers state-of-the-art milling machines with innovative features like adaptive controls and advanced automation. Their machines are renowned for precision and reliability.

HAAS Automation

HAAS provides versatile and affordable milling machines suited for various industries. Their user-friendly CNC systems make them a favorite among toolmakers.

Makino

Makino specializes in high-performance milling machines designed for intricate tool making. Their machines feature cutting-edge technology, including thermal stability and vibration control.

Okuma

Okuma delivers robust milling solutions with advanced CNC capabilities. Their machines are ideal for tool making, offering excellent accuracy and efficiency.

Maintaining Your High Tech Milling Machine

Regular Cleaning and Lubrication

Keep your machine clean and well-lubricated to ensure smooth operation. Remove chips and debris after each use to prevent damage and maintain precision.

Schedule Preventive Maintenance

Follow the manufacturer’s recommended maintenance schedule to address potential issues before they escalate. Regular inspections extend the machine’s lifespan and optimize performance.

Update Software and Firmware

Ensure your machine’s software and firmware are up to date. Updates often include performance enhancements and bug fixes, improving overall functionality.

Innovations Driving the Future of Milling Machines

AI and Machine Learning

Artificial intelligence is enabling smarter, more adaptive milling machines. AI-driven systems analyze data to optimize cutting paths and improve efficiency in real time.

Additive and Subtractive Hybrid Machines

Hybrid machines combine milling and 3D printing, offering unmatched versatility. These systems allow for both additive manufacturing and traditional subtractive machining in a single device.

Eco-Friendly Designs

Manufacturers are focusing on sustainability by developing energy-efficient machines and incorporating recyclable materials. These innovations reduce environmental impact without compromising performance.

Why High Tech Milling Machines Are Worth the Investment

Competitive Advantage

Investing in high tech milling machines gives manufacturers a competitive edge. Their advanced capabilities enable the production of complex tools that meet modern industry standards.

Scalability and Flexibility

These machines adapt to changing production needs, whether it’s scaling up for larger orders or shifting to specialized projects. Their versatility ensures long-term usability.

Enhanced Productivity

With features like automation and CNC integration, high tech milling machines streamline workflows and boost productivity. Faster production times mean quicker delivery and higher customer satisfaction.

Conclusion: Transforming Tool Making with Advanced Milling Machines

High tech milling machines for tool making are revolutionizing the manufacturing landscape. Their precision, efficiency, and adaptability empower toolmakers to tackle complex projects and deliver exceptional results.

Whether creating molds, dies, or custom tools, these machines offer unparalleled advantages. Investing in the right milling technology not only enhances productivity but also sets the stage for long-term success in a competitive market. Upgrade your operations today and experience the power of innovation.